Your core business is what you would like to, focus…

Your core business is what you would like to, focus and grow ? given the current climate you should be…

At Kimelind, we are dedicated to providing world-class engineering solutions and advanced coating services tailored to meet the unique needs of our diverse clientele. Our expertise spans multiple disciplines, enabling us to deliver innovative, high-quality, and reliable results that set industry standards.

From precision engineering to specialized coating applications, our team of experienced professionals combines technical excellence with cutting-edge technologies to solve complex challenges. Whether you require surface protection, enhanced performance, or tailored solutions, Kimelind is your trusted partner in achieving excellence and durability.

Connect with us today to explore how we can bring your vision to life with expertise that you can count on.

For inquiries or to discuss your project needs, feel free to reach out to us at sales@Kimelind.com

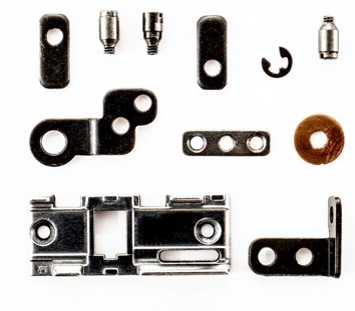

We provide a comprehensive range of fasteners designed to meet diverse industrial and specialized needs. Our offerings cover everything from small-volume standard fasteners to large-volume specialized fasteners, ensuring solutions for both common applications and highly specific requirements.

Our fasteners are available in a variety of manufacturing processes to suit your needs, including:

We utilize a wide range of high-quality materials tailored to your application, including steel, stainless steel, and exotic alloys. In addition, our fasteners can be finished with advanced coatings to enhance performance, durability, and corrosion resistance. Examples of these finishes include:

Specialty Fasteners with Pre-Applied Solutions

To further enhance the functionality of our fasteners, we also offer specialty options with pre-applied thread lockers and sealants from leading manufacturers. These pre-applied solutions ensure secure, vibration-resistant fastening and leak-proof sealing right out of the box, reducing installation time and improving reliability.

Whether your needs involve precision-engineered components, large-scale production, or tailored solutions, we are committed to delivering fasteners that exceed expectations in quality, performance, and efficiency.

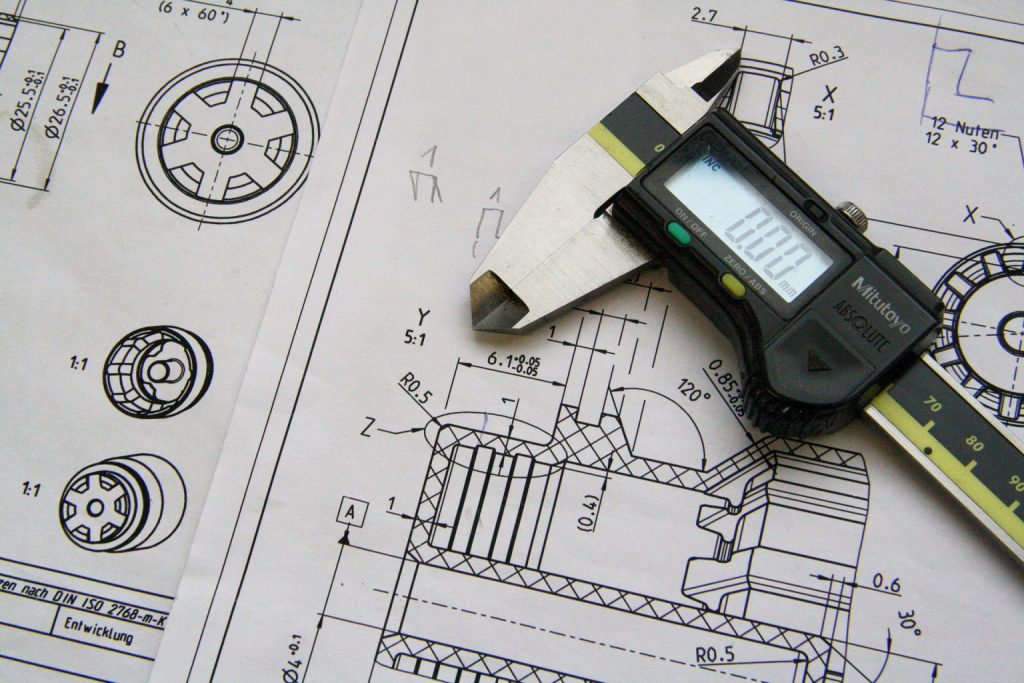

Designing: Expertise That Drives Success

Our team brings over 40 years of combined experience in Specialized Application Engineering, making us a trusted partner in guiding you from the very beginning of your project—right at the design stage.

The design phase is a crucial foundation for any engineering or manufacturing project. Engaging our experts early in the process ensures that your requirements are fully understood, potential challenges are identified, and optimal solutions are implemented from the outset. This proactive approach not only enhances the quality and performance of the final product but also significantly reduces the time, effort, and costs associated with revisions and unforeseen issues later in the project lifecycle.

Through collaboration during the design stage, we provide insights into material selection, manufacturing processes, and specialized coatings to ensure your project is tailored to meet both functional and cost-efficiency goals. By consulting with us early, you can rest assured that your project is set up for success, avoiding delays and unnecessary expenses while achieving the highest standards of performance and reliability.

Let us assist you in turning your vision into reality—seamlessly and efficiently—starting with a robust and well-informed design.

Precision CNC Manufacturing and Complex Engineered Components

We specialize in the production of precision CNC and highly complex engineered components, crafted to your exact specifications. Utilizing advanced technologies, including specialized equipment, we deliver high-quality components manufactured from a wide range of materials to meet diverse industry needs.

Our services extend beyond standard materials to include high-performance plastics and sintered parts, ensuring we can support applications requiring unique properties such as lightweight strength, durability, or heat resistance. Each component is produced with meticulous attention to detail and accompanied by the appropriate finish as specified in your drawings.

By leveraging cutting-edge equipment and our team's expertise, we provide reliable and efficient solutions, whether for small-scale custom orders or larger production volumes.

Suppliers of Custom Stainless Steel and Powder Metal Components

We proudly supply high-quality custom stainless steel and powder metal components to meet the diverse needs of our clients. Partnering with manufacturers that hold IATF 16949 certification, we ensure that the components we provide adhere to the highest standards of quality and reliability, particularly for automotive and other demanding industries.

Our partners are equipped with advanced powder metal production and testing equipment, employing rigorous quality assurance systems and innovative processes. This allows us to supply precision-engineered sintered components designed for applications requiring enhanced strength, durability, and material efficiency.

With a focus on delivering tailored solutions and exceptional service, we provide components that meet your exact specifications, whether for small-scale projects or large-scale production needs. Our commitment to excellence ensures that every component supplied supports the success of your projects.

Comprehensive Casting Solutions

We provide a broad range of high-quality casting services to meet diverse industry requirements. Our expertise spans various casting methods, ensuring we can deliver components tailored to your exact specifications and performance needs.

Our casting capabilities include:

By leveraging these diverse casting techniques, we are able to supply components that meet stringent quality and performance standards. Whether you need precision parts for small-scale applications or larger, more robust components, our casting solutions are designed to provide exceptional reliability and value.

Our team works closely with clients to ensure the right casting method and materials are selected, optimizing your project for both performance and cost-efficiency.

Sheet Metal Fabrication, Precision Stamping, and CNC Wire Bending Solutions

We provide a comprehensive range of services catering to highly specialized requirements across industries such as white goods, food and beverage, and construction. From simple 2D shapes to intricate geometries requiring multiple stages and operations, we deliver precision-engineered solutions tailored to your needs.

Our capabilities include:

Sheet Metal Fabrication

Precision Stamping and Press Components

Laser Cutting and Folding

Water Jet Cutting

CNC Wire Bending

Welding Services

Cold Forging

By combining these advanced techniques and processes, we provide end-to-end solutions for manufacturing high-quality components that meet the specific demands of your industry. Whether your requirements involve custom designs, small production runs, or large-scale manufacturing, our expertise ensures reliable, cost-effective results tailored to your exact needs.

High-Precision Tool Design for Injection Molding Components

We specialize in providing high-precision tool design for injection molding components across various sectors, including automotive, industrial, electrical, and particularly the food industry. Our expertise in tool design ensures that the components we create are optimized for durability, functionality, and efficiency, tailored to meet the unique demands of each sector.

In the food industry, we have extensive experience designing tooling for components such as proofer baskets, food-grade containers, and storage racks—all requiring high precision and adherence to strict hygiene and safety standards.

Additionally, we design tools for other specialized applications, including overholding tools and specialty filter meshes, crucial for filtration and material separation processes.

To ensure the consistency and quality of our designs, we offer in-house testing capabilities and can also produce small pilot batches. This allows us to validate the performance of the tooling and ensure the parts meet all required specifications before scaling up to full production.

By working closely with our clients, we deliver custom tooling solutions that enhance product quality and production efficiency across a wide range of industries.

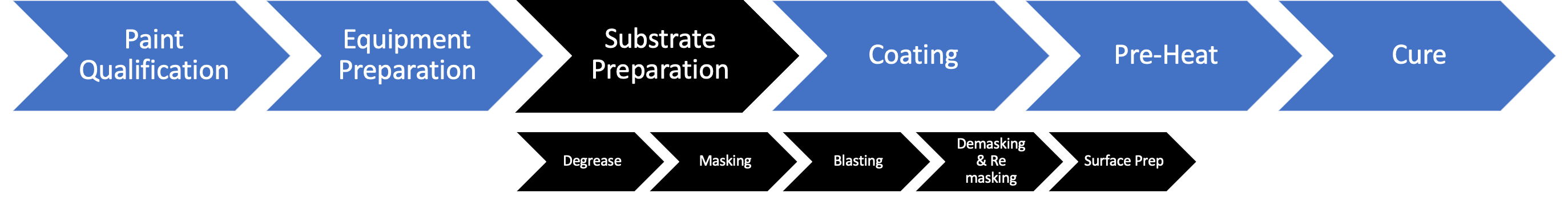

Specialized Coatings for Enhanced Product Performance

At every stage of your coating process, we are here to assist with troubleshooting, design, and providing expert advice to help you select the best coating solution for your specific application. Whether you’re looking to enhance product performance, extend service life, or improve reliability, we are committed to offering tailored solutions that help your business stay ahead of the curve.

Our extensive experience spans across industries such as the food and chemical industries, where we have applied specialized coatings to meet the most demanding requirements. Some of the coatings we provide include:

Food Industry Coatings

In the food industry, where hygiene and durability are paramount, we offer coatings that protect against corrosion, wear, and contaminants, while maintaining compliance with industry standards. Examples include:

Chemical Industry Coatings

In the chemical industry, where components often face exposure to harsh chemicals and extreme temperatures, we provide specialized coatings that offer superior resistance to aggressive substances. Some examples include:

Combining Technologies for Unique Solutions

We utilize a variety of coating technologies, often combining different approaches to deliver solutions that are specifically designed for your needs. Whether it’s applying zinc flake coatings for enhanced corrosion resistance or using ceramic coatings for thermal protection, we ensure that every solution is crafted to meet the specific demands of your industry and application.

Our focus on delivering customized coating solutions ensures that your products perform optimally in even the harshest environments, providing durability, reliability, and extended service life.

Let us guide you through the coating process, providing expert support from initial design to application and beyond, so your products stand up to the toughest conditions and provide lasting value to your business.

“Skate to where the puck is going to be, not where it has been“

“There are no straight lines or sharp corners in nature,”

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Your core business is what you would like to, focus and grow ? given the current climate you should be…

To accommodate this they would need to invest hundreds of thousands to get started and due to the market condition…

In today’s fast-paced business environment, is your core business getting the attention it deserves? Or are you spending valuable time…