Reverse Engineering Bakery Equipment Parts

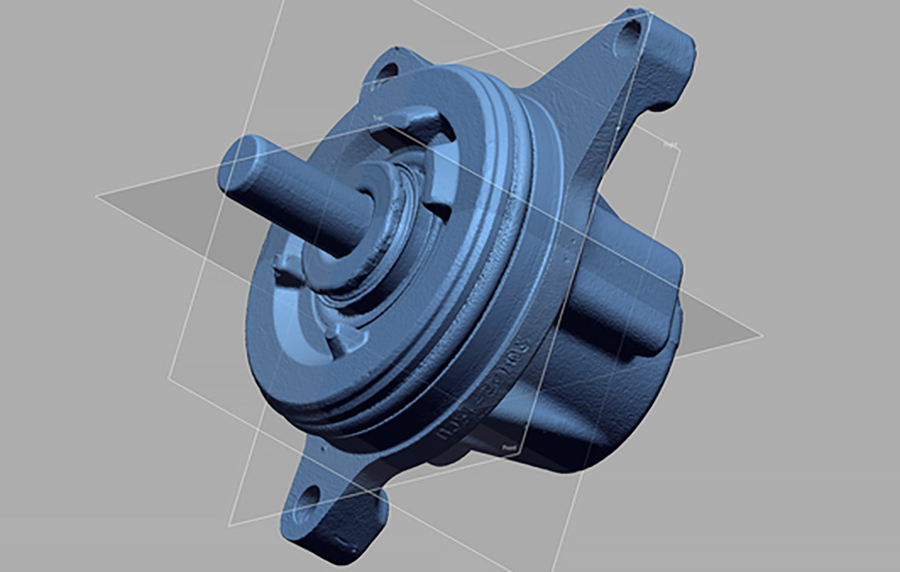

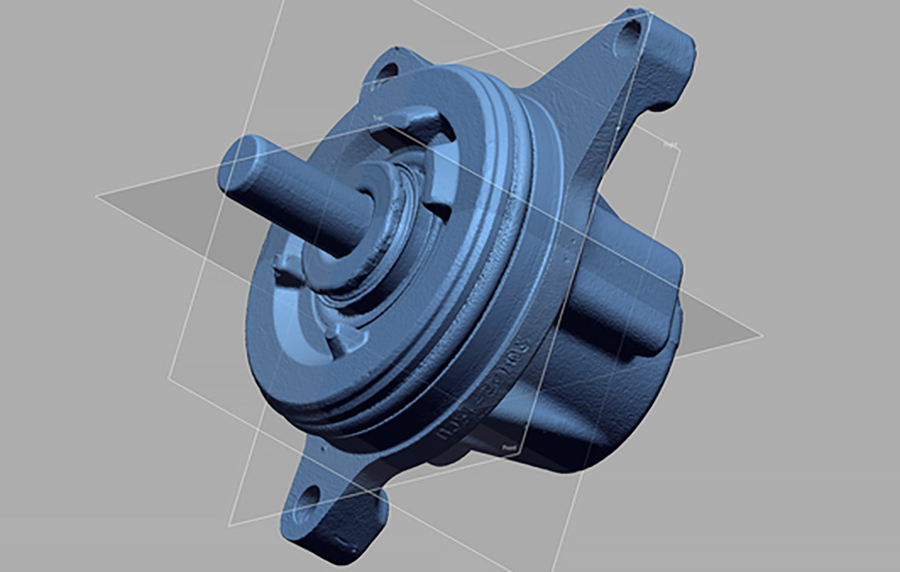

When critical parts for bakery machinery are no longer available from the original manufacturer, reverse engineering allows businesses to reproduce these components. This involves creating precise CAD (Computer-Aided Design) models based on the original part and using advanced manufacturing techniques to produce new ones.

Key Steps:

Inspection and Measurement:

1.Physically measure the existing part (if available) using tools like calipers, micrometers, or 3D scanners.

2.Example: A worn-out roller from a dough sheeter can be scanned to capture its dimensions and surface contours.

CAD Modeling:

1.Translate the measurements into detailed CAD drawings that specify the part’s geometry, materials, and tolerances.

2.Example: A broken gear from an industrial bread slicer can be converted into a CAD model to ensure precision.

Material Selection and Manufacturing:

1.Choose suitable materials, such as exotic metals or specialized plastics, to meet the bakery equipment's operational demands.

2.Example: Replace a high-temperature oven conveyor component with a new one made from heat-resistant stainless steel.

Production and Testing:

1.Manufacture the part using processes like CNC machining, injection molding, or 3D printing.

2.Test the new part to ensure it integrates seamlessly into the machinery.

Examples of Bakery Equipment Reverse Engineering:

Obsolete Bearings for Mixers:

1.A bakery mixer’s bearing is no longer produced. Reverse engineering creates a CAD model of the worn bearing, and a replacement is manufactured using modern materials with better durability.

Custom Conveyor Chains:

1.Conveyor systems for proofing chambers often use unique chains that wear out over time. Reverse engineering replaces these with corrosion-resistant alternatives, enhancing the system's longevity.

Exotic Metal Blades for Dough Cutters:

1.Blades that were originally made of exotic steel alloys for cutting sticky dough are replicated using reverse engineering. The CAD process ensures precise replication and compatibility.

Plastic Components for Packaging Machines:

1.Outdated plastic guides or cogs in packaging machines can be reverse-engineered and manufactured from food-grade polymers, ensuring safety and compliance with regulations.

Heating Elements for Ovens:

1.When heating elements fail in older ovens, reverse engineering allows for the creation of compatible replacements using advanced heat-resistant alloys.

Why Reverse Engineering is Critical in Bakery Operations

Here is a list of different machining processes used to manufacture components from specialty plastics like PEEK and PTFE, and metals like brass, stainless steel, and steel, along with relevant examples and industries:

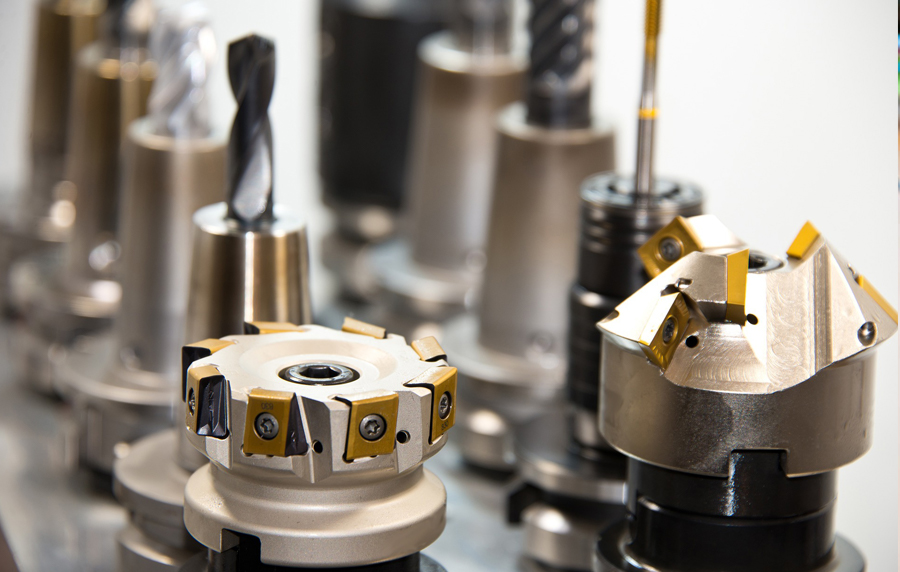

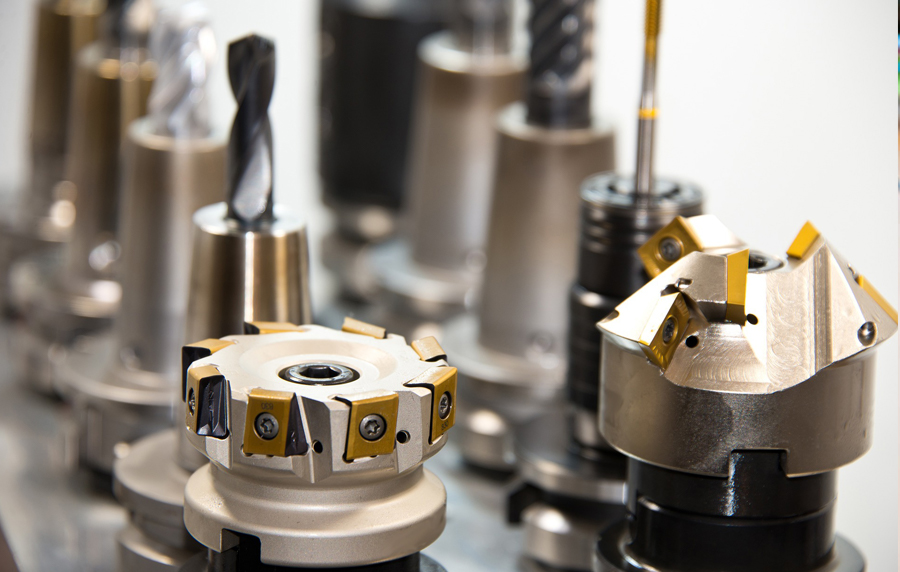

Process: CNC (Computer Numerical Control) milling uses rotary cutters to remove material from a workpiece, allowing for precise cutting and shaping of complex parts.

Turning (Lathe Machining)

Process: Turning uses a rotating workpiece and stationary cutting tool to remove material, typically to create cylindrical shapes, threads, or smooth surfaces.

Grinding

Process: Grinding involves using an abrasive wheel to smooth or finish surfaces, typically used for high-precision applications and creating tight tolerances.

Electrical Discharge Machining (EDM)

Process: EDM uses electrical discharges (sparks) to erode material from the workpiece, ideal for hard metals or complex, delicate parts.

Laser Cutting

Process: Laser cutting uses a focused laser beam to melt or vaporize material to create precise cuts in various shapes.

Water Jet Cutting

Process: Water jet cutting uses high-pressure water mixed with abrasive materials to cut through thick materials without generating heat.

Drilling

Process: Drilling involves creating round holes in a workpiece using a rotating drill bit.

Milling

Process: Milling involves using rotary cutters to remove material from a workpiece, creating flat surfaces or complex shapes.

Polishing

Process: Polishing is a finishing process that smooths the surface of a part to achieve a shiny, smooth finish, typically using abrasive compounds.

Each of these machining processes allows for the creation of precision components from specialty plastics like PEEK and PTFE, and metals like brass, stainless steel, and steel, catering to various industries such as aerospace, automotive, medical, electronics, and manufacturing. The choice of machining process depends on the material properties, complexity of the part, and the required tolerances.

Examples of Sheet Metal Fabrication in Various Industries

Laser-Cut Trays

Folded Sheet Metal Components

Complex Sheet Metal Stampings

Perforated Metal Panels

Custom Enclosures and Covers

Here are some examples of casting processes used to produce smaller, lighter, and non-critical components across various industries:

Sand Casting

➡️ Components & Industries:

Die Casting

➡️ Components & Industries:

Investment Casting (Lost Wax Casting)

➡️ Components & Industries:

Low-Pressure Die Casting

➡️ Components & Industries:

Permanent Mold Casting

➡️ Components & Industries:

These components, are still essential in various industries for functionality, aesthetics, and manufacturing processes. They typically do not require the high-performance characteristics needed in critical applications but benefit from the casting processes' cost-effectiveness and ability to produce detailed shapes.

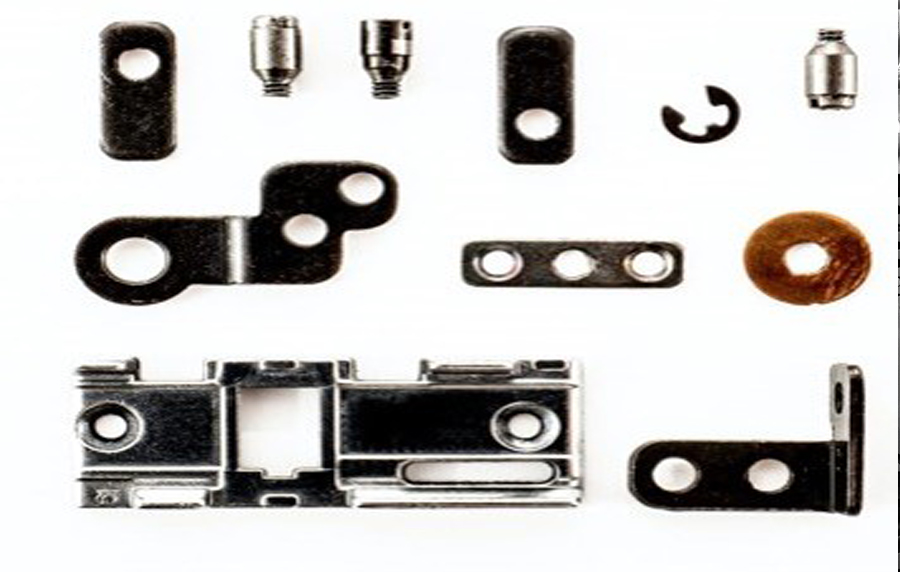

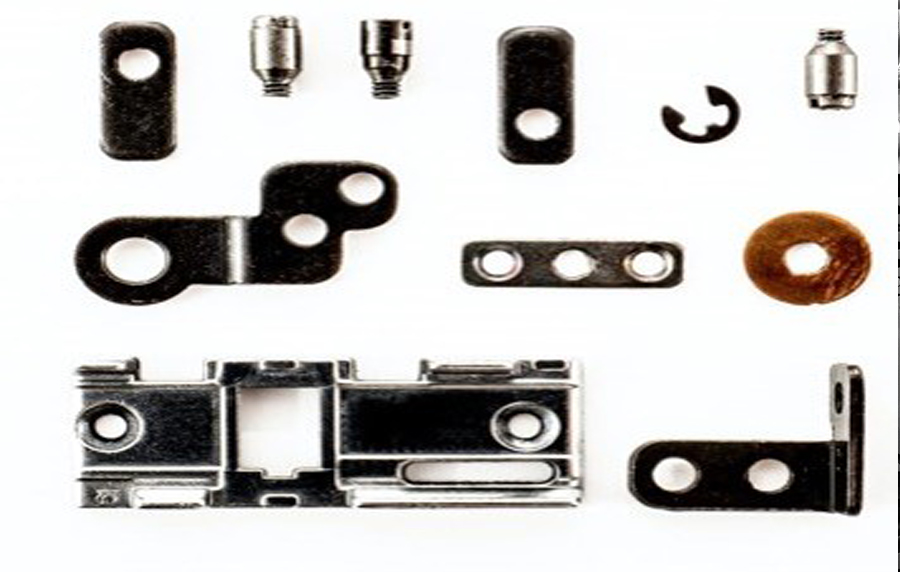

Special fasteners are uniquely designed components created to meet specific requirements beyond standard fasteners. They serve specialized functions in industries like aerospace, automotive, and construction where durability, unique shapes, or enhanced corrosion resistance are essential. Common types include self-tapping screws, captive fasteners, and custom bolts, each tailored to particular applications. Special fasteners provide increased strength, reliability, and adaptability, often crafted from materials like stainless steel, titanium, or alloys for enhanced performance.

Injection Molding Applications: Plastic Components Across Industries

Injection molding is a versatile manufacturing process used to produce a wide range of plastic components with precision and efficiency. This process is essential for creating durable, lightweight, and cost-effective parts for various industries. Below is an expanded explanation with specific examples.

Examples of Injection Molding Applications

Engine Parts:

Machinery Parts:

Material Considerations

Advantages of Injection Molding

1.High Efficiency:

1.Suitable for mass production with consistent quality and tight tolerances.

2.Versatility:

1.Capable of creating complex shapes, overmolded parts, and multi-material components.

3.Durability:

1.Ideal for components that must withstand mechanical stress, high temperatures, or corrosive environments.

4.Cost-Effective:

1.Low material waste and scalability for large production runs.

Injection molding is a cornerstone of modern manufacturing, enabling the production of essential components for appliances, automotive systems, medical devices, and more. Its adaptability, combined with innovations like overmolding, makes it indispensable for industries requiring precision, durability, and efficiency.

We also specialize in manufacturing custom tools tailored to customer-supplied drawings. For example, we can design and produce high-quality plastic injection molds to meet specific project requirements. Our process includes comprehensive services such as precision manufacturing, tool testing, and validation. For customers requiring prototypes or limited production runs, we offer small-scale production testing to ensure the tool meets all performance criteria. Once completed, the tools are delivered ready for seamless

Reverse Engineering Bakery Equipment Parts

When critical parts for bakery machinery are no longer available from the original manufacturer, reverse engineering allows businesses to reproduce these components. This involves creating precise CAD (Computer-Aided Design) models based on the original part and using advanced manufacturing techniques to produce new ones.

Key Steps:

Inspection and Measurement:

1.Physically measure the existing part (if available) using tools like calipers, micrometers, or 3D scanners.

2.Example: A worn-out roller from a dough sheeter can be scanned to capture its dimensions and surface contours.

CAD Modeling:

1.Translate the measurements into detailed CAD drawings that specify the part’s geometry, materials, and tolerances.

2.Example: A broken gear from an industrial bread slicer can be converted into a CAD model to ensure precision.

Material Selection and Manufacturing:

1.Choose suitable materials, such as exotic metals or specialized plastics, to meet the bakery equipment's operational demands.

2.Example: Replace a high-temperature oven conveyor component with a new one made from heat-resistant stainless steel.

Production and Testing:

1.Manufacture the part using processes like CNC machining, injection molding, or 3D printing.

2.Test the new part to ensure it integrates seamlessly into the machinery.

Examples of Bakery Equipment Reverse Engineering:

Obsolete Bearings for Mixers:

1.A bakery mixer’s bearing is no longer produced. Reverse engineering creates a CAD model of the worn bearing, and a replacement is manufactured using modern materials with better durability.

Custom Conveyor Chains:

1.Conveyor systems for proofing chambers often use unique chains that wear out over time. Reverse engineering replaces these with corrosion-resistant alternatives, enhancing the system's longevity.

Exotic Metal Blades for Dough Cutters:

1.Blades that were originally made of exotic steel alloys for cutting sticky dough are replicated using reverse engineering. The CAD process ensures precise replication and compatibility.

Plastic Components for Packaging Machines:

1.Outdated plastic guides or cogs in packaging machines can be reverse-engineered and manufactured from food-grade polymers, ensuring safety and compliance with regulations.

Heating Elements for Ovens:

1.When heating elements fail in older ovens, reverse engineering allows for the creation of compatible replacements using advanced heat-resistant alloys.

Why Reverse Engineering is Critical in Bakery Operations

Here is a list of different machining processes used to manufacture components from specialty plastics like PEEK and PTFE, and metals like brass, stainless steel, and steel, along with relevant examples and industries:

Process: CNC (Computer Numerical Control) milling uses rotary cutters to remove material from a workpiece, allowing for precise cutting and shaping of complex parts.

Turning (Lathe Machining)

Process: Turning uses a rotating workpiece and stationary cutting tool to remove material, typically to create cylindrical shapes, threads, or smooth surfaces.

Grinding

Process: Grinding involves using an abrasive wheel to smooth or finish surfaces, typically used for high-precision applications and creating tight tolerances.

Electrical Discharge Machining (EDM)

Process: EDM uses electrical discharges (sparks) to erode material from the workpiece, ideal for hard metals or complex, delicate parts.

Laser Cutting

Process: Laser cutting uses a focused laser beam to melt or vaporize material to create precise cuts in various shapes.

Water Jet Cutting

Process: Water jet cutting uses high-pressure water mixed with abrasive materials to cut through thick materials without generating heat.

Drilling

Process: Drilling involves creating round holes in a workpiece using a rotating drill bit.

Milling

Process: Milling involves using rotary cutters to remove material from a workpiece, creating flat surfaces or complex shapes.

Polishing

Process: Polishing is a finishing process that smooths the surface of a part to achieve a shiny, smooth finish, typically using abrasive compounds.

Each of these machining processes allows for the creation of precision components from specialty plastics like PEEK and PTFE, and metals like brass, stainless steel, and steel, catering to various industries such as aerospace, automotive, medical, electronics, and manufacturing. The choice of machining process depends on the material properties, complexity of the part, and the required tolerances.

Examples of Sheet Metal Fabrication in Various Industries

Laser-Cut Trays

Folded Sheet Metal Components

Complex Sheet Metal Stampings

Perforated Metal Panels

Custom Enclosures and Covers

Here are some examples of casting processes used to produce smaller, lighter, and non-critical components across various industries:

Sand Casting

➡️ Components & Industries:

Die Casting

➡️ Components & Industries:

Investment Casting (Lost Wax Casting)

➡️ Components & Industries:

Low-Pressure Die Casting

➡️ Components & Industries:

Permanent Mold Casting

➡️ Components & Industries:

These components, are still essential in various industries for functionality, aesthetics, and manufacturing processes. They typically do not require the high-performance characteristics needed in critical applications but benefit from the casting processes' cost-effectiveness and ability to produce detailed shapes.

Special fasteners are uniquely designed components created to meet specific requirements beyond standard fasteners. They serve specialized functions in industries like aerospace, automotive, and construction where durability, unique shapes, or enhanced corrosion resistance are essential. Common types include self-tapping screws, captive fasteners, and custom bolts, each tailored to particular applications. Special fasteners provide increased strength, reliability, and adaptability, often crafted from materials like stainless steel, titanium, or alloys for enhanced performance.

These components, are still essential in various industries for functionality, aesthetics, and manufacturing processes. They typically do not require the high-performance characteristics needed in critical applications but benefit from the casting processes' cost-effectiveness and ability to produce detailed shapes.

Injection Molding Applications: Plastic Components Across Industries

Injection molding is a versatile manufacturing process used to produce a wide range of plastic components with precision and efficiency. This process is essential for creating durable, lightweight, and cost-effective parts for various industries. Below is an expanded explanation with specific examples.

Examples of Injection Molding Applications

Engine Parts:

Machinery Parts:

Material Considerations

Advantages of Injection Molding

1.High Efficiency:

1.Suitable for mass production with consistent quality and tight tolerances.

2.Versatility:

1.Capable of creating complex shapes, overmolded parts, and multi-material components.

3.Durability:

1.Ideal for components that must withstand mechanical stress, high temperatures, or corrosive environments.

4.Cost-Effective:

1.Low material waste and scalability for large production runs.

Injection molding is a cornerstone of modern manufacturing, enabling the production of essential components for appliances, automotive systems, medical devices, and more. Its adaptability, combined with innovations like overmolding, makes it indispensable for industries requiring precision, durability, and efficiency.

We also specialize in manufacturing custom tools tailored to customer-supplied drawings. For example, we can design and produce high-quality plastic injection molds to meet specific project requirements. Our process includes comprehensive services such as precision manufacturing, tool testing, and validation. For customers requiring prototypes or limited production runs, we offer small-scale production testing to ensure the tool meets all performance criteria. Once completed, the tools are delivered ready for seamless